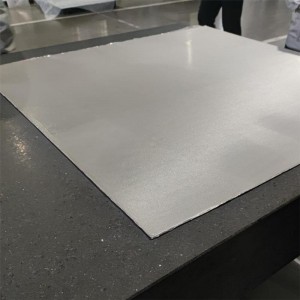

Structure

Specifications

Materials

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Other materials available on request.

Filter fineness: 1 –100 microns

| Descriptsion |

filter fineness |

Structure |

Thickness |

Porosity |

Air Permeability |

Rp |

Weight |

Bubble Pressure |

|

μm |

mm |

% |

(L/min/cm²) |

N / cm |

kg / ㎡ |

(mmH₂O) |

||

|

SSM-F-1 |

1 |

100+400x2800+100+12/64+64/12 |

1.7 |

37 |

1.82 |

1080 |

8.4 |

360-600 |

|

SSM-F-2 |

2 |

100+325x2300+100+12/64+64/12 |

1.7 |

37 |

2.36 |

1080 |

8.4 |

300-590 |

|

SSM-F-5 |

5 |

100+200x1400+100+12/64+64/12 |

1.7 |

37 |

2.42 |

1080 |

8.4 |

260-550 |

|

SSM-F-10 |

10 |

100+165x1400+100+12/64+64/12 |

1.7 |

37 |

3.08 |

1080 |

8.4 |

220-500 |

|

SSM-F-15 |

15 |

100+165x1200+100+12/64+64/12 |

1.7 |

37 |

3.41 |

1080 |

8.4 |

200-480 |

|

SSM-F-20 |

20 |

100+165x800+100+12/64+64/12 |

1.7 |

37 |

4.05 |

1080 |

8.4 |

170-450 |

|

SSM-F-25 |

25 |

100+165x600+100+12/64+64/12 |

1.7 |

37 |

6.12 |

1080 |

8.4 |

150-410 |

|

SSM-F-30 |

30 |

100+400+100+12/64+64/12 |

1.7 |

37 |

6.7 |

1080 |

8.4 |

120-390 |

|

SSM-F-40 |

40 |

100+325+100+12/64+64/12 |

1.7 |

37 |

6.86 |

1080 |

8.4 |

100-350 |

|

SSM-F-50 |

50 |

100+250+100+12/64+64/12 |

1.7 |

37 |

8.41 |

1080 |

8.4 |

90-300 |

|

SSM-F-75 |

75 |

100+200+100+12/64+64/12 |

1.7 |

37 |

8.7 |

1080 |

8.4 |

80-250 |

|

SSM-F-100 |

100 |

100+150+100+12/64+64/12 |

1.7 |

37 |

9.1 |

1080 |

8.4 |

70-190 |

Size

500mmx1000mm,1000mmx1000mm

600mmx1200mm,1200mmx1200mm

1200mmx1500mm,1500mmx2000mm

Application

Fluidised beds, Nutsche filters, Centrifuges, Aeration of silos, applications in biotechnology.

Note

LCL means less than one container loaded

FCL means full container loaded

Five-layer sintered mesh is usually used for purification and filtration of liquids and gases, separation and recovery of solid particles, evaporative cooling at high temperatures, distribution of airflow control, enhanced heat and mass transfer, noise reduction, flow limitation, etc.

The five-layer sintered mesh consists of an interconnected network of filter holes of uniform height with tortuous paths that trap solid particles in gas or liquid. It can be used to filter smoke and dust in high-temperature flue gas. It can withstand high temperatures up to 600°C. It has high strength and is easy to shape.

1. Precise filtration of various hydraulic oil lubricants in the machinery industry;

2. Filtration and purification of various polymer melts in the chemical fiber film industry, filtration of various high-temperature and corrosive liquids in the petrochemical industry, filtration, washing and drying of materials in the pharmaceutical industry;

3. Application of gas homogenization in powder industry, fluidized plate in steel industry;

4. Distributors in explosion-proof electrical appliances, etc.