Structure

Materials

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Other materials available on request.

Filter fineness: 1 –100 microns

Specifications

|

Specification -Standard five-layer sintered mesh |

||||||||

|

Description |

filter fineness |

Structure |

Thickness |

Porosity |

Air Permeability |

Rp |

Weight |

Bubble Pressure |

|

μm |

mm |

% |

(L/min/cm²) |

N / cm |

kg / ㎡ |

(mmH₂O) |

||

|

SSM-F-1 |

1 |

100+400x2800+100+12/64+64/12 |

1.7 |

37 |

1.82 |

1080 |

8.4 |

360-600 |

|

SSM-F-2 |

2 |

100+325x2300+100+12/64+64/12 |

1.7 |

37 |

2.36 |

1080 |

8.4 |

300-590 |

|

SSM-F-5 |

5 |

100+200x1400+100+12/64+64/12 |

1.7 |

37 |

2.42 |

1080 |

8.4 |

260-550 |

|

SSM-F-10 |

10 |

100+165x1400+100+12/64+64/12 |

1.7 |

37 |

3.08 |

1080 |

8.4 |

220-500 |

|

SSM-F-15 |

15 |

100+165x1200+100+12/64+64/12 |

1.7 |

37 |

3.41 |

1080 |

8.4 |

200-480 |

|

SSM-F-20 |

20 |

100+165x800+100+12/64+64/12 |

1.7 |

37 |

4.05 |

1080 |

8.4 |

170-450 |

|

SSM-F-25 |

25 |

100+165x600+100+12/64+64/12 |

1.7 |

37 |

6.12 |

1080 |

8.4 |

150-410 |

|

SSM-F-30 |

30 |

100+400+100+12/64+64/12 |

1.7 |

37 |

6.7 |

1080 |

8.4 |

120-390 |

|

SSM-F-40 |

40 |

100+325+100+12/64+64/12 |

1.7 |

37 |

6.86 |

1080 |

8.4 |

100-350 |

|

SSM-F-50 |

50 |

100+250+100+12/64+64/12 |

1.7 |

37 |

8.41 |

1080 |

8.4 |

90-300 |

|

SSM-F-75 |

75 |

100+200+100+12/64+64/12 |

1.7 |

37 |

8.7 |

1080 |

8.4 |

80-250 |

|

SSM-F-100 |

100 |

100+150+100+12/64+64/12 |

1.7 |

37 |

9.1 |

1080 |

8.4 |

70-190 |

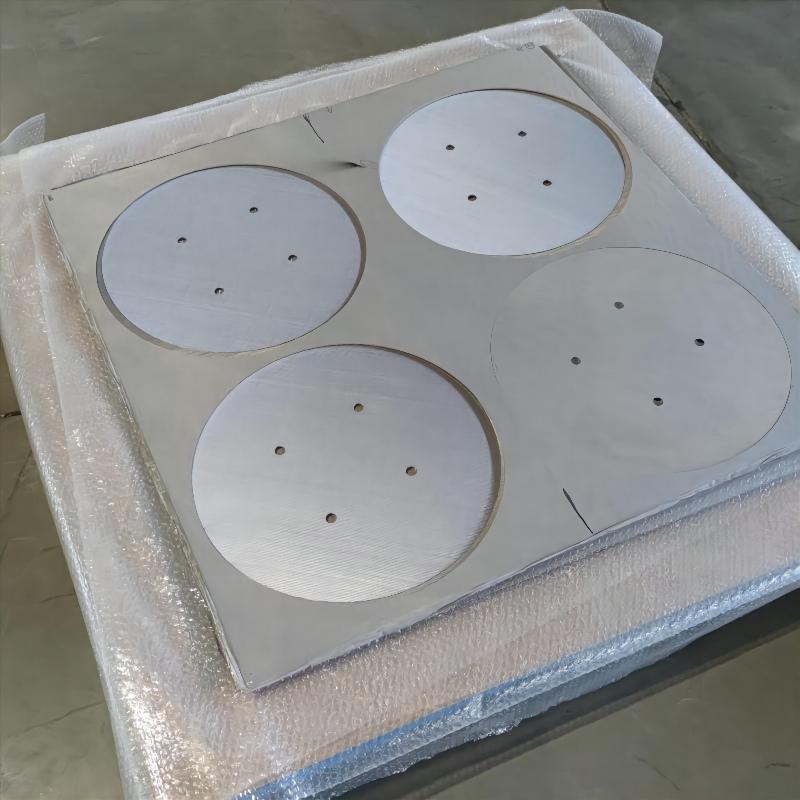

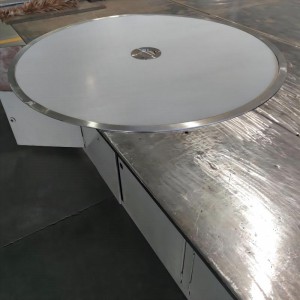

Size

Diameter: 5mm-1500mm

Larger than 1500mm, we need to splice.

Applications

Fluidised beds, Nutsche filters, Centrifuges, Aeration of silos, applications in biotechnology.

The standard five-layer sintered mesh structure is divided into four parts: protective layer, filter layer, dispersion layer and skeleton layer. This kind of filter material not only has uniform and stable filtration accuracy but also has high strength and rigidity. It is an ideal filter material for occasions where uniform precision is required. Because its filtration mechanism is surface filtration, and the mesh channel is smooth, it has excellent backwash regeneration performance and can be used repeatedly for a long time, especially suitable for continuous and automatic operation processes, which is unmatched by any filter material . The material is easy to form, process and weld, and can be processed into various forms of filter elements such as round, cylindrical, conical and corrugated.

characteristic

1. High strength and good rigidity: It has high mechanical strength and compressive strength, good processing, welding and assembly performance, and easy to use.

2. Uniform and stable precision: Uniform and consistent filtration performance can be achieved for all filtration precisions, and the mesh does not change during use.

3. Wide range of use environments: it can be used in the temperature environment of -200 ℃ ~ 600 ℃ and the filtration of acid-base environment.

4. Excellent cleaning performance: good countercurrent cleaning effect, can be used repeatedly, and has a long service life (can be cleaned by countercurrent water, filtrate, ultrasonic, melting, baking, etc.).

The company has international advanced production equipment, a first-class R&D team, a professional technical team, an efficient sales network, and a complete after-sales service system. We will continue to improve our own quality and level, and continue to meet the various needs of customers with excellent quality and thoughtful service.