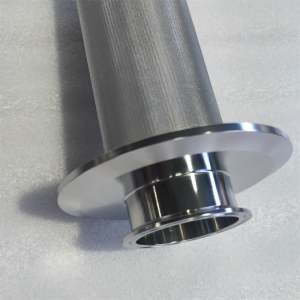

Structure

Materials

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Other materials available on request.

Filter fineness: 1 –100 microns

Specifications

|

Specification -Standard five-layer sintered mesh |

||||||||

|

Description |

filter fineness |

Structure |

Thickness |

Porosity |

Air Permeability |

Rp |

Weight |

Bubble Pressure |

|

μm |

mm |

% |

(L/min/cm²) |

N / cm |

kg / ㎡ |

(mmH₂O) |

||

|

SSM-F-1 |

1 |

100+400x2800+100+12/64+64/12 |

1.7 |

37 |

1.82 |

1080 |

8.4 |

360-600 |

|

SSM-F-2 |

2 |

100+325x2300+100+12/64+64/12 |

1.7 |

37 |

2.36 |

1080 |

8.4 |

300-590 |

|

SSM-F-5 |

5 |

100+200x1400+100+12/64+64/12 |

1.7 |

37 |

2.42 |

1080 |

8.4 |

260-550 |

|

SSM-F-10 |

10 |

100+165x1400+100+12/64+64/12 |

1.7 |

37 |

3.08 |

1080 |

8.4 |

220-500 |

|

SSM-F-15 |

15 |

100+165x1200+100+12/64+64/12 |

1.7 |

37 |

3.41 |

1080 |

8.4 |

200-480 |

|

SSM-F-20 |

20 |

100+165x800+100+12/64+64/12 |

1.7 |

37 |

4.05 |

1080 |

8.4 |

170-450 |

|

SSM-F-25 |

25 |

100+165x600+100+12/64+64/12 |

1.7 |

37 |

6.12 |

1080 |

8.4 |

150-410 |

|

SSM-F-30 |

30 |

100+400+100+12/64+64/12 |

1.7 |

37 |

6.7 |

1080 |

8.4 |

120-390 |

|

SSM-F-40 |

40 |

100+325+100+12/64+64/12 |

1.7 |

37 |

6.86 |

1080 |

8.4 |

100-350 |

|

SSM-F-50 |

50 |

100+250+100+12/64+64/12 |

1.7 |

37 |

8.41 |

1080 |

8.4 |

90-300 |

|

SSM-F-75 |

75 |

100+200+100+12/64+64/12 |

1.7 |

37 |

8.7 |

1080 |

8.4 |

80-250 |

|

SSM-F-100 |

100 |

100+150+100+12/64+64/12 |

1.7 |

37 |

9.1 |

1080 |

8.4 |

70-190 |

Applications

Fluidised beds, Nutsche filters, Centrifuges, Aeration of silos, applications in biotechnology.

The principle of sintered mesh: perforated plate composite sintered mesh is composed of standard material punched plate (round hole or square hole) and several layers of square hole mesh (or dense mesh) composite sintering as a whole, which has the good air permeability of flat woven mesh properties, and the mechanical strength of the perforated plate. Not only has good air permeability, but also has the characteristics of low pressure difference, high precision, and more excellent back cleaning. It has been widely used in water treatment, beverage, food, metallurgy, chemical and pharmaceutical industries. At the same time, our company can design special distribution network according to the customer's working conditions, and produce punched plate composite sintered network made of Monel, dual-phase steel, titanium alloy and other materials.

Sintered mesh features:

1. Sintered mesh has high strength and good rigidity: it has high mechanical strength and compressive strength, good processing, welding and assembly performance, and is easy to use.

2. Uniform and stable precision of sintered mesh: Uniform and consistent filtration performance can be achieved for all filtration precisions, and the mesh does not change during use.

3. Standard five-layer net: it consists of four parts: protective layer, filter layer, separation layer and two-layer support layer.

4. Sintered mesh has high strength and good rigidity: it has extremely high mechanical strength and compressive strength.