Structure

Materials

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Other materials available on request.

Filter fineness: 1 –100 microns

Specifications

|

Specification -Standard five-layer sintered mesh |

||||||||

|

Description |

filter fineness |

Structure |

Thickness |

Porosity |

Air Permeability |

Rp |

Weight |

Bubble Pressure |

|

μm |

mm |

% |

(L/min/cm²) |

N / cm |

kg / ㎡ |

(mmH₂O) |

||

|

SSM-F-1 |

1 |

100+400x2800+100+12/64+64/12 |

1.7 |

37 |

1.82 |

1080 |

8.4 |

360-600 |

|

SSM-F-2 |

2 |

100+325x2300+100+12/64+64/12 |

1.7 |

37 |

2.36 |

1080 |

8.4 |

300-590 |

|

SSM-F-5 |

5 |

100+200x1400+100+12/64+64/12 |

1.7 |

37 |

2.42 |

1080 |

8.4 |

260-550 |

|

SSM-F-10 |

10 |

100+165x1400+100+12/64+64/12 |

1.7 |

37 |

3.08 |

1080 |

8.4 |

220-500 |

|

SSM-F-15 |

15 |

100+165x1200+100+12/64+64/12 |

1.7 |

37 |

3.41 |

1080 |

8.4 |

200-480 |

|

SSM-F-20 |

20 |

100+165x800+100+12/64+64/12 |

1.7 |

37 |

4.05 |

1080 |

8.4 |

170-450 |

|

SSM-F-25 |

25 |

100+165x600+100+12/64+64/12 |

1.7 |

37 |

6.12 |

1080 |

8.4 |

150-410 |

|

SSM-F-30 |

30 |

100+400+100+12/64+64/12 |

1.7 |

37 |

6.7 |

1080 |

8.4 |

120-390 |

|

SSM-F-40 |

40 |

100+325+100+12/64+64/12 |

1.7 |

37 |

6.86 |

1080 |

8.4 |

100-350 |

|

SSM-F-50 |

50 |

100+250+100+12/64+64/12 |

1.7 |

37 |

8.41 |

1080 |

8.4 |

90-300 |

|

SSM-F-75 |

75 |

100+200+100+12/64+64/12 |

1.7 |

37 |

8.7 |

1080 |

8.4 |

80-250 |

|

SSM-F-100 |

100 |

100+150+100+12/64+64/12 |

1.7 |

37 |

9.1 |

1080 |

8.4 |

70-190 |

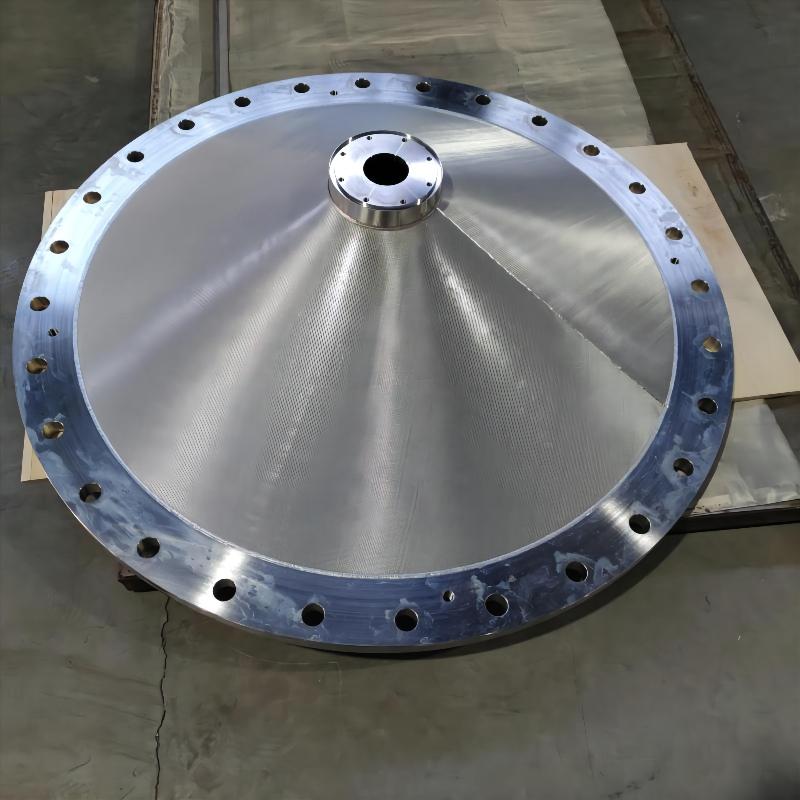

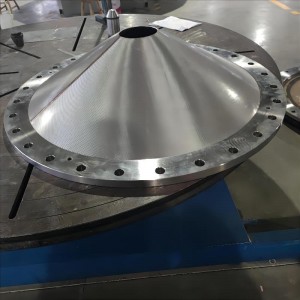

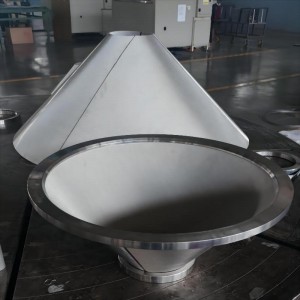

Characteristics of stainless steel conical sintered mesh filter element

1. Filtration is stable and uniform: protected by upper and lower layers of wire mesh, combined with the sintering process of diffusion and solid fusion, the filter mesh is not easy to deform, and can achieve uniform filtration performance for all filtration precisions, suitable for continuous and automation process.

2. Good strength: supported by the reinforcement layer and the support layer, it has high mechanical strength and compressive strength.

3. Easy processing: suitable for cutting, bending, stamping, stretching, welding and other processing techniques, easy to use.

4. Wide range of material selection: 316L, 304, 321, etc. can be used.

5. Corrosion resistance: due to the use of SUS316L and 304 materials, it has strong corrosion resistance and is suitable for filtration in acid-base environments.

6. Wide range of use environments: it can be used in temperature environments from -200°C to 600°C.

7. Easy to clean: due to the fixed mesh shape, uniform pore size, smooth and simple channels and the use of surface filter materials, it is easy to clean (can be cleaned by countercurrent water, ultrasonic melting and baking of filtrate, etc.), can be used repeatedly, Long life characteristics.

Stainless steel conical sintered mesh filter element application range

1. Liquid and gas filtration in petrochemical, polyester, pharmaceutical, food and beverage and water treatment industries;

2. High-pressure medium filtration; Oilfield oil sand separation;

3. Machinery, ships, fuel, lubricating oil, hydraulic starting oil;

4. Process filtration for complete sets of chemical equipment in the chemical industry;

5. High temperature gas sterilization, water treatment, also used for filtration of media such as water and air.

Applications

Fluidised beds, Nutsche filters, Centrifuges, Aeration of silos, applications in biotechnology.