Structure

Materials

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Other materials available on request.

Filter fineness: 1 –200 microns

Specifications

|

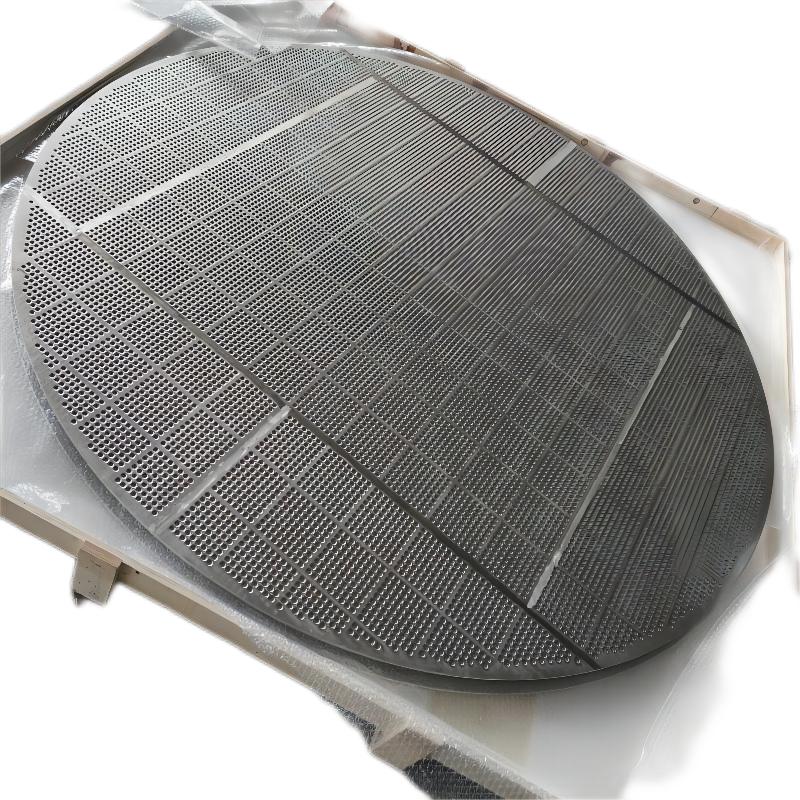

Specification - Punching plate sintered wire mesh |

||||

|

Description |

filter fineness |

Structure |

Thickness |

Porosity |

|

μm |

mm |

% |

||

|

SSM-P-1.5T |

2-100 |

60+filter layer+60+30+Φ4x5px1.0T |

1.5 |

57 |

|

SSM-P-2.0T |

2-100 |

30+filter layer+30+Φ5x7px1.5T |

2 |

50 |

|

SSM-P-2.5T |

20-100 |

60+filter layer+60+30+Φ4x5px1.5T |

2.5 |

35 |

|

SSM-P-3.0T |

2-200 |

60+filter layer+60+20+Φ6x8px2.0T |

3 |

35 |

|

SSM-P-4.0T |

2-200 |

30+filter layer+30+20+Φ8x10px2.5T |

4 |

50 |

|

SSM-P-5.0T |

2-200 |

30+filter layer+30+20+16+10+Φ8x10px3.0T |

5 |

55 |

|

SSM-P-6.0T |

2-250 |

30+filter layer+30+20+16+10+Φ8x10px4.0T |

6 |

50 |

|

SSM-P-7.0T |

2-250 |

30+filter layer+30+20+16+10+Φ8x10px5.0T |

7 |

50 |

|

SSM-P-8.0T |

2-250 |

30+filter layer+30+20+16+10+Φ8x10px6.0T |

8 |

50 |

|

The thickness of the punching plate and structure of the wire mesh can be customized according to the user’s requirements. |

||||

Remarks, if it is used in Multifunctional filter washing dryers, the filter plate structure can be standard five-layer and punching plate sintered together.

That is 100+filter layer+100+12/64+64/12+4.0T(or Of other thickness punching plate)

The thickness of punching plate is also depended on your pressure demand.

This product is ideal for high pressure environments or high pressure backwashing demand, effectively solve the continuous production of pharmaceutical and chemical industry and online backwashing, sterile production requirements.

Applications

Food&beverage, water treatment, dust removing, pharmacy, chemical, polymer,etc.

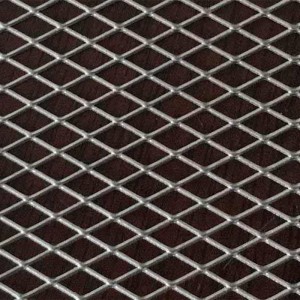

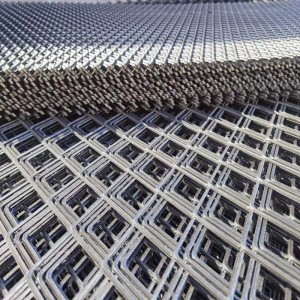

The perforated plate sintered mesh is a kind of sintered mesh that sinters the porous plate and the base flat woven mesh together. The punching plate can be selected in different thicknesses according to the needs, and the plain weaving net can be one or more layers. Due to the punching plate as support, the composite mesh has high compressive strength and mechanical strength. The sintering of the two not only has the good air permeability of the flat woven mesh, but also has the mechanical strength of the porous plate. It can be processed into cylindrical, disc, sheet and cone filters, widely used in water treatment, beverage, food, metallurgy, chemical and pharmaceutical industries, etc.

Perforated plate sintered mesh features:

(1) Good rigidity and high mechanical strength. Because of the punching plate support, it has the highest mechanical strength and compressive strength among sintered meshes;

(2) High filtration precision, the range of filtration precision is 1μ-100μ, and it has reliable filtration performance;

(3) Easy to clean, the surface filter is adopted, especially suitable for backwashing;

(4) It is not easily deformed, the shape of the mesh is fixed, the size of the gap is uniform, and there is no blind hole.

(5) Corrosion resistance, high temperature resistance, can withstand high temperature of 480 ℃.

Perforated plate sintered mesh use:

(1) Materials used for dispersive cooling in extremely high temperature environments.

(2) For the application of gas uniformity in the powder industry, fluidized plates in the steel industry.

(3) Orifice plate material for gas distribution fluidized bed.

(4) It is used in blast furnace injection pulverized coal flow and dense phase conveying system.

(5) Filtration, washing and drying of materials in the pharmaceutical industry.

(6) Catalyst support grille.

(7) It is used for filtration of polyester, oil, food and beverage, chemical fiber products, and also for water treatment and gas filtration.