Structure

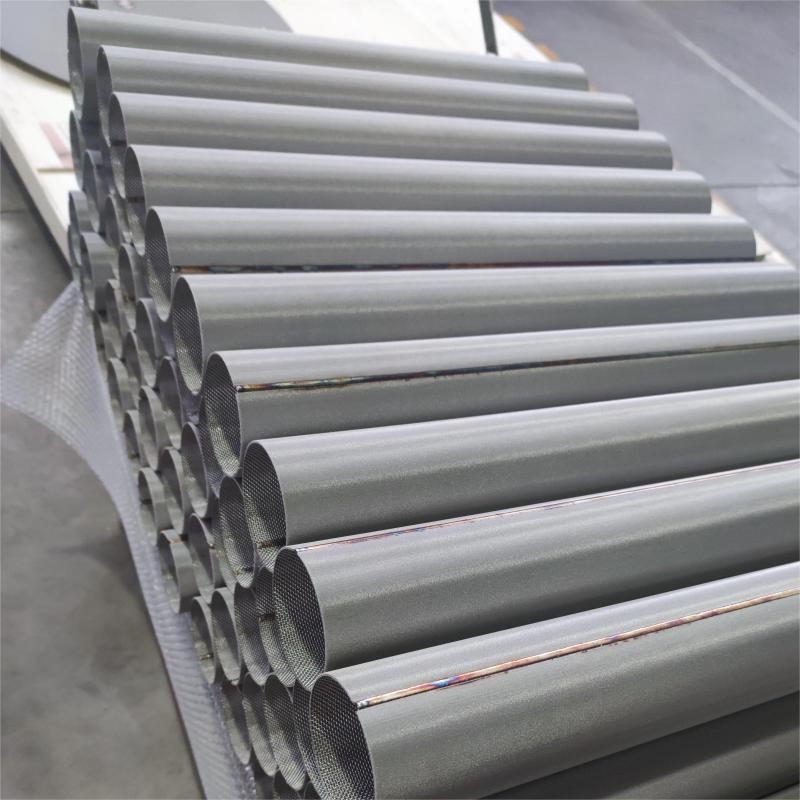

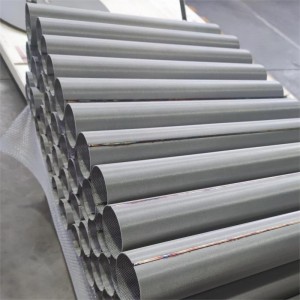

Model one

Model two

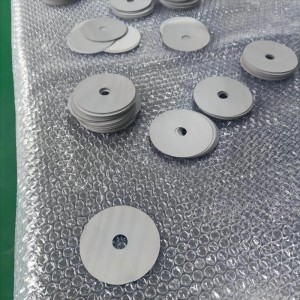

Two or Three same mesh sintered into on piece

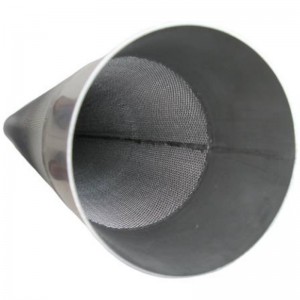

Model three

Materials

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Other materials available on request.

Filter fineness: 1 –200 microns

Specifications

|

Specification - Two or three - layer sintered mesh |

|||||

|

Description |

filter fineness |

Structure |

Thickness |

Porosity |

Weight |

|

μm |

mm |

% |

kg / ㎡ |

||

|

SSM-T-0.5T |

2-200 |

filter layer+80 |

0.5 |

50 |

1 |

|

SSM-T-1.0T |

20-200 |

filter layer+20 |

1 |

55 |

1.8 |

|

SSM-T-1.8T |

125 |

16+20+24/110 |

1.83 |

46 |

6.7 |

|

SSM-T-2.0T |

100-900 |

filter layer+10 |

1.5-2.0 |

65 |

2.5-3.6 |

|

SSM-T-2.5T |

200 |

12/64+64/12+12/64 |

3 |

30 |

11.5 |

|

Remarks:Other layer structure available on request |

|||||

Applications

Fluidisation elements, fluidised bed floors,aeration elements, pneumatic conveyor troughs.etc.

The filtration accuracy of the stainless steel mesh sintered cylindrical filter element is above 0.5~200um.

The sintered stainless steel mesh cylindrical filter element has the characteristics of high precision, good permeability, high strength, strong corrosion resistance, easy cleaning and back cleaning, not easy to damage, and no material separation.

Stainless steel mesh sintered cylindrical filter element is mainly used for filtration of polyester, oil products, pharmaceuticals, food and beverage, chemical products, and also for filtration of media such as water and air.

Stainless steel mesh sintered cylindrical filter elements cover a wide range of sizes and specifications. All size specifications can be designed and produced according to customer requirements, and suitable products can also be designed and recommended according to operating conditions and requirements.

Material: stainless steel SUS304, SUS316L, etc., super stainless steel: Monel, Hastelloy, etc.

The main twelve advantages and characteristics of the stainless steel mesh sintered cylindrical filter element of the stainless steel filter element series are as follows:

1. Filtration technology adopts international advanced high-precision vacuum welding, and original standardized technical process (we will continue to innovate and develop, and there will be more ultra-precision filtration technologies to serve the world in the future);

2. The current accuracy range: from 0.5 to 200 microns and above, with a wide range of applicable accuracy;

3. High mechanical strength, good rigidity and extremely stable precision. The high pressure resistance performance is very outstanding, especially suitable for occasions that require high compressive strength and uniform filter particle size;

4. Low filter impedance and very good permeability;

5. The material is high-quality food hygiene grade stainless steel, which has very good wear resistance;

6. Originally created the world's advanced precision manufacturing technology, the filter element is smooth and easy to clean, without any material falling off;

7. The cold resistance is very good, and the low temperature can reach below -220 degrees (special ultra-low working temperature can be customized);

8. The heat resistance is very good, and the operating temperature can reach above 650 degrees (special ultra-high operating temperature can be customized);

9. Resistant to working environments such as strong alkali and strong acid corrosion;

10. The filtration mechanism is surface filtration, and the mesh channel is smooth, so it has excellent backwash regeneration performance and can be used repeatedly for a long time, especially suitable for continuous and automatic operation processes, which is unmatched by any filter material of;

11. The scope of application is very wide, suitable for various gases, liquids, solids, sound waves, light, explosion-proof, etc. (main connection methods: standard interface, <such as 222, 220, 226>, quick interface connection, screw connection, French Lan connection, tie rod connection, special custom interface, etc.);

12. The overall performance is obviously superior to other types of filter materials such as sintered powder, ceramics, fiber, filter cloth, filter paper, etc. It has special advantages such as high precision, high efficiency and long life.