Structure

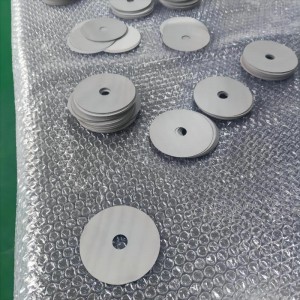

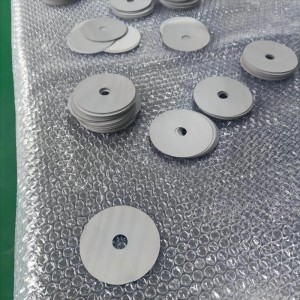

Model one

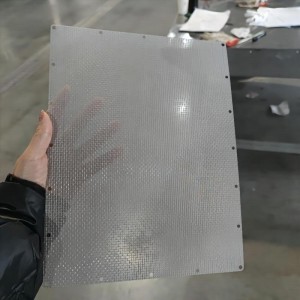

Model two

Two or Three same mesh sintered into on piece

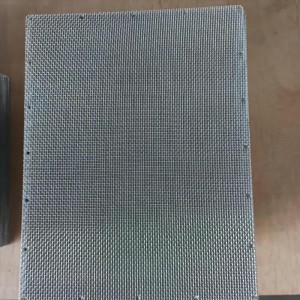

Model three

Materials

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Other materials available on request.

Filter fineness: 1 –200 microns

Size

500mmx1000mm,1000mmx1000mm

600mmx1200mm,1200mmx1200mm

1200mmx1500mm,1500mmx2000mm

Other size available on request.

Specifications

|

Specification - Two or three - layer sintered mesh |

|||||

|

Description |

filter fineness |

Structure |

Thickness |

Porosity |

Weight |

|

μm |

mm |

% |

kg / ㎡ |

||

|

SSM-T-0.5T |

2-200 |

filter layer+80 |

0.5 |

50 |

1 |

|

SSM-T-1.0T |

20-200 |

filter layer+20 |

1 |

55 |

1.8 |

|

SSM-T-1.8T |

125 |

16+20+24/110 |

1.83 |

46 |

6.7 |

|

SSM-T-2.0T |

100-900 |

filter layer+10 |

1.5-2.0 |

65 |

2.5-3.6 |

|

SSM-T-2.5T |

200 |

12/64+64/12+12/64 |

3 |

30 |

11.5 |

|

Remarks:Other layer structure available on request |

|||||

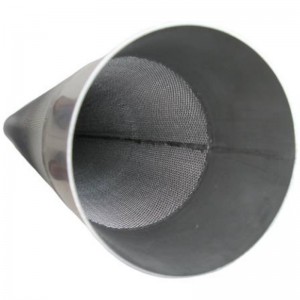

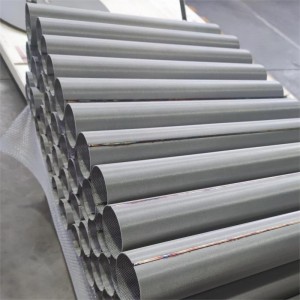

Applications

Fluidisation elements, fluidised bed floors, aeration elements, pneumatic conveyor troughs, etc.

This is a kind of sintered net made by stacking two or three layers of flat-woven dense nets with the same precision and crossed together through sintering, pressing, rolling and other processes. It has the characteristics of uniform mesh distribution and stable air permeability. Mainly used in fluidized bed, powder conveying, noise reduction, drying, cooling and other fields.