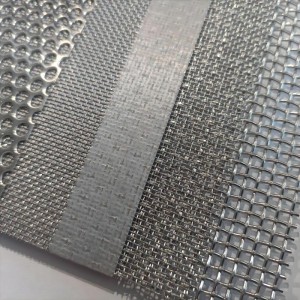

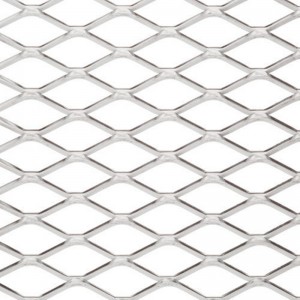

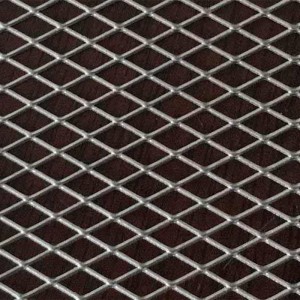

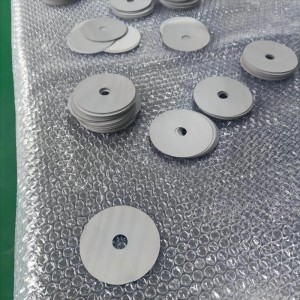

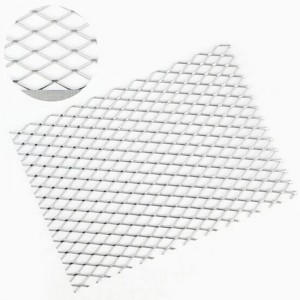

Structure

Materials

DIN 1.4404/AISI 316L, DIN 1.4539/AISI 904L

Monel, Inconel, Duples steel, Hastelloy alloys

Other materials available on request.

Filter fineness: 1 –200 microns

Specifications

|

Specification - Punching plate sintered wire mesh |

||||

|

Description |

filter fineness |

Structure |

Thickness |

Porosity |

|

μm |

mm |

% |

||

|

SSM-P-1.5T |

2-100 |

60+filter layer+60+30+Φ4x5px1.0T |

1.5 |

57 |

|

SSM-P-2.0T |

2-100 |

30+filter layer+30+Φ5x7px1.5T |

2 |

50 |

|

SSM-P-2.5T |

20-100 |

60+filter layer+60+30+Φ4x5px1.5T |

2.5 |

35 |

|

SSM-P-3.0T |

2-200 |

60+filter layer+60+20+Φ6x8px2.0T |

3 |

35 |

|

SSM-P-4.0T |

2-200 |

30+filter layer+30+20+Φ8x10px2.5T |

4 |

50 |

|

SSM-P-5.0T |

2-200 |

30+filter layer+30+20+16+10+Φ8x10px3.0T |

5 |

55 |

|

SSM-P-6.0T |

2-250 |

30+filter layer+30+20+16+10+Φ8x10px4.0T |

6 |

50 |

|

SSM-P-7.0T |

2-250 |

30+filter layer+30+20+16+10+Φ8x10px5.0T |

7 |

50 |

|

SSM-P-8.0T |

2-250 |

30+filter layer+30+20+16+10+Φ8x10px6.0T |

8 |

50 |

|

The thickness of the punching plate and structure of the wire mesh can be customized according to the user’s requirements. |

||||

Remarks, if it is used in Multifunctional filter washing dryers, the filter plate structure can be standard five-layer and punching plate sintered together.

That is 100+filter layer+100+12/64+64/12+4.0T(or Of other thickness punching plate)

The thickness of punching plate is also depended on your pressure demand

This product is ideal for high pressure environments or high pressure backwashing demand, effectively solve the continuous production of pharmaceutical and chemical industry and online backwashing, sterile production requirements.

Applications

Food&beverage, water treatment, dust removing, pharmacy, chemical, polymer,etc.

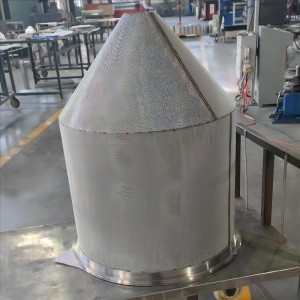

Conical filter cartridges are named for their shape. It belongs to the simplest filter form of the pipeline coarse filter series. It can remove large solid impurities in the fluid when installed on the pipeline, so that the machinery and equipment (including compressors, pumps, etc.) and instruments can work and operate normally, and achieve stable process. The role of ensuring safe production. When the fluid enters the filter cartridge with a filter screen of a certain specification, the impurities are blocked, and the clean filtrate is discharged from the filter outlet. When cleaning is required, just take out the detachable filter cartridge and reinstall it after treatment. Yes, therefore, it is extremely convenient to use and maintain. Temporary filter features: It is mainly used before the start-up of the equipment pipeline, installed between the two flanges of the pipeline, and removes impurities in the pipeline; the equipment is simple, reliable, and has a wide range of applications.